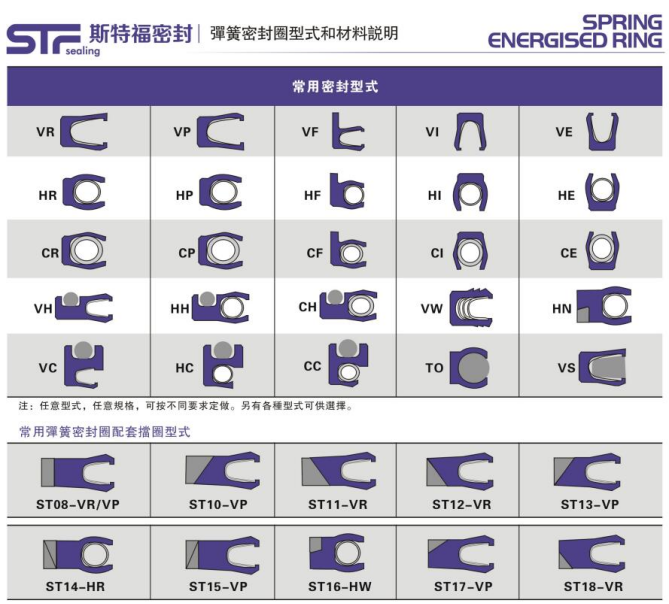

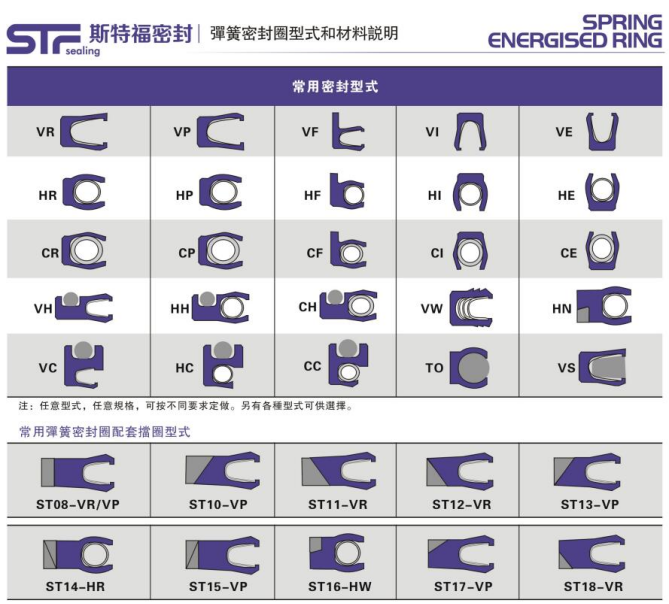

Seal lips come in a variety of designs. This will achieve a sealed condition and reduce friction. In this way, the life of the seal is longer. The metal spring ensures that the seal lip is protected from leakage, even under no-pressure conditions. Make up for various thermal expansion phenomena.

On a liquid rocket engine, various valves are an indispensable part. In the eyes of rocket engine designers, valves are devices that change fluid flow or flow characteristics, and control the state of the engine through the control of gas and propellant flow and pressure.

We may not understand much here, in fact, you can understand the valve as a super complex faucet, or a super complex gas stove, how much water, how much fire, rely on it to control.

Since the valve is to control the liquid and gas, then the problem is: the liquid and gas will leak! Not to mention that the main propellant that flows through the valve of the rocket engine is the propellant, whether it is toxic nitrous oxide and undimethylhydrazine, or the volatile liquid hydrogen and oxygen that explodes at once, even kerosene and methane, which seem to be safer fuels, are also extremely dangerous if leaked. Therefore, to ensure that the valve does not leak is a very important issue.

Sealed "professionalism" - no leakage

The root cause of leakage is a machining problem, in the process of turning the product, it is inevitable to produce a variety of defects, uneven, or dimensional deviations, you know, the world's grinding machine can not do a completely flat processing surface. Therefore, there will inevitably be gaps in the connection of mechanical parts, and these gaps are leakage channels; The second reason is that there is a pressure difference on both sides of the seal, and the working medium will leak through the gap.

Most of the rocket propellant is in a pressurized state, when it passes through the valve, due to the effect of pressure, it naturally squeezes out, and it will go out when it encounters a gap. If the image is understood a little, just like the medical syringes we often see, if the rubber end on the middle push rod and the syringe are not sealed, the liquid will leak out along the gap between the two. If the gap is large enough, then the push rod and the syringe are like two unrelated objects, and they will completely fail. The structure and operation of the valve are of course much more complex, but the consequences caused by leakage are the same.

The main way to prevent leakage is to reduce or eliminate the gap, that is, seal the gap between the components to prevent the leakage of the media inside, or increase the pressure outside these gaps, so that the internal and external pressure difference is partially offset or completely balanced to reduce or eliminate leakage.

For sealing, it is mainly divided into static sealing and dynamic sealing. Static seal is well understood, is the seal between the static surface, mainly used between the relatively static joint surface. Dynamic sealing technology is relatively complex, but if you go back to the previous syringe example, you can also easily understand. But the operating environment of the rocket engine valve is much more complicated than the needle. For example, during rocket flight, the valve has to experience the influence of changes in the temperature and pressure of the external environment, and at the same time, it has to be subjected to the violent vibration generated by the engine working and the high temperature generated by the fuel burning. In the face of the currently widely used low-temperature liquid fuel, the valve has to undergo a more severe test, one side is flame baking, the other is low-temperature fuel, which can be described as fire and ice.

At this time, the pan plug seal has become a good choice among many material seals.

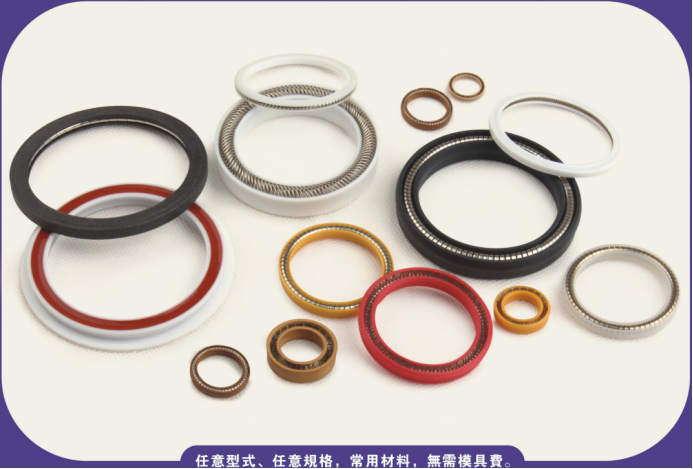

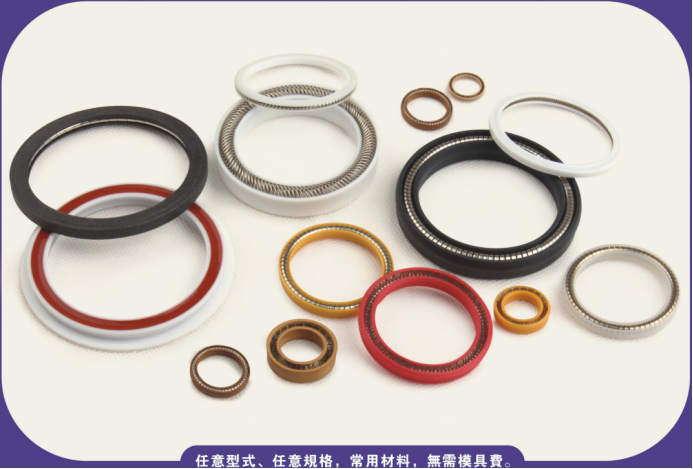

Pan-plug Seal is the transliteration of the English "Variseal", meaning composite seal, combined seal, mainly refers to the Spring energy storage seal (PTFE Spring Energized Seal). The pan plug seal is a pressure auxiliary sealing device composed of a non-metal jacket and a spring. Its sealing jacket is made of high-performance polymer polymer material by precision turning U-shaped shell, the spring is made of corrosion-resistant metal, the sealing ring is suitable for the temperature range from -268 ° C to 427 ° C, stable performance. The pan plug seal is installed in the sealing groove, and the spring will press the lip edge of the jacket close to the sealing groove to form the initial sealing force. The medium pressure will also provide the sealing force. The higher the medium pressure, the greater the medium sealing force. By means of spring elasticity and system pressure, effective sealing can be achieved at both high and low pressures.

The choice of pan-plug seal for aerospace cryogenic valve is not accidental, and it has the following characteristics:

Pan plug seal has been widely used in many industries, and has successfully become automotive sealing rings, mechanical industry sealing rings, food equipment sealing rings, petrochemical sealing rings, crane pipe joint sealing rings, dispensing machine sealing rings, pharmaceutical sealing rings, mature products are naturally more assured.

2. The application of pan plug seal in ultra-low temperature and high pressure liquid rocket engine will produce many advantages. For example, it can effectively reduce the size of the low-temperature dynamic seal and optimize the engine structure. The same sealing specifications, the weight of the plug seal is about 70% to 80% lighter than other dynamic sealing structures, the structure size is about 70% smaller, and the life is more than 10 times longer.

3. Pan-plug sealing technology is mature and cheap, which can effectively save development costs, shorten the development cycle, and reduce the difficulty of machining. Compared with other dynamic seal structures, the development cycle of the pan plug seal can be completed within one month, and the procurement cost is one-tenth of the bellows.

4. Good versatility. The successful development experience of the ultra-low temperature engine valve with the pan plug sealing structure can also be applied to the dynamic seal structure of other professional engines and rocket bodies, which is very suitable for the rapid iteration requirements of commercial aerospace.

In order to meet the requirements of low cost, high reliability and rapid iteration of ultra-low temperature liquid oxygen methane engine developed by aerospace, the domestic aviation industry adopts the dynamic sealing technology of pan-plug sealing.

In order to overcome the ultra-low temperature and high pressure flooding seal dynamic sealing technology, STF seal with domestic valve professional engineers after years of research and development work, respectively, starting from the material, structure and other key points of the flooding seal and dynamic seal lip, after several rounds of exploration and testing, determined the suitable for ultra-low temperature liquid oxygen, liquid methane, liquid nitrogen and helium media. The pressure range covers low, medium and high pressure plug seal structures, forming a complete set of plug seal design standards and selection catalog.

To meet the needs of different customers, there are hundreds of different pan-plug seal structures available for customers in different industries.

According to the requirements of the ultra-low temperature liquid oxygen methane engine system, combined with the characteristics of the pan plug seal structure, STF seal innovatively designed a variety of ultra-low temperature and high pressure valves. The valves have passed a series of tests at normal temperature, low temperature, vibration, life, natural environment, etc., and the valves equipped with pan plug seals operate reliably according to the engine timing, with stable performance, meeting the requirements of the engine system.

STF sealing sincerely look forward to the arrival of every customer with sealing needs, and contribute their own strength to the sealing of all walks of life in China, and realize the dream of sealing the country.